The Six Big Losses: What They Are and How to Minimize Them

Don't know how to tackle the Six Big Losses in your factory? Here's how to do this and improve your plant's OEE at the same time.

One way to improve your overall equipment effectiveness (OEE) is to eliminate what’s known as the Six Big Losses.

This model, which has its roots in total productive maintenance (TPM), serves as an effective framework for improving your operations and achieving greater efficiency on the shop floor.

What are the Six Big Losses?

The Six Big Losses are a way of categorizing the different kinds of equipment-related losses. They fall into three categories: availability, performance, and quality.

Let’s walk through them one by one.

1. Availability: Unplanned stops

Unplanned stops occur when equipment is not working due to breakdowns, maintenance activities, or failures that occur within time that’s scheduled for production.

2. Availability: Planned stops

Planned stops are the reverse: these include scheduled downtime for maintenance, changeovers, cleaning , and so on.

3. Performance: Small stops

A small stop refers to when equipment shuts down for a period lower than 10 minutes. They are often persistent and may occur multiple times a day.

4. Performance: Slow cycles

This loss occurs when a machine runs at a slower speed compared to its ideal cycle time. This could be due to inadequate CIL activities or maintenance.

5. Quality: Production rejects

This is a quality loss that takes the form of scrapped parts generated during the production process or parts that must be reworked.

6. Quality: Startup rejects

Lastly, startup loss results in scrapped or reworked parts. These losses occur after any equipment startup or after changeovers.

If you’re new to tackling the Six Big Losses, it’s best to start with the availability loss category, as planned and unplanned stops tend to be the easiest to track and are the biggest, most visible ones.

However, keep in mind you can start anywhere — and may choose to do so based on the priorities of your industry.

For example, a pharmaceutical or food and beverage business will probably concentrate on quality losses before availability and performance losses.

How Digitization Can Help

Understanding and minimizing the Six Big Losses requires greater visibility into siloed or difficult-to-monitor production processes.

In fact, some losses, like small stops and slow cycle speeds, are really difficult to measure using pen and paper. At the same time, they easily add up in terms of lost production time and costs.

Fortunately, connected worker platforms offer all the necessary tools you need to not only measure and monitor the Six Big Losses, but to do so more efficiently — enabling you to improve your OEE in the process.

Keep unplanned and planned stops to a minimum

One way to reduce unplanned stops is to empower your operators to perform cleaning, inspection, and lubrication (CIL) tasks, as well as other small maintenance activities, independently.

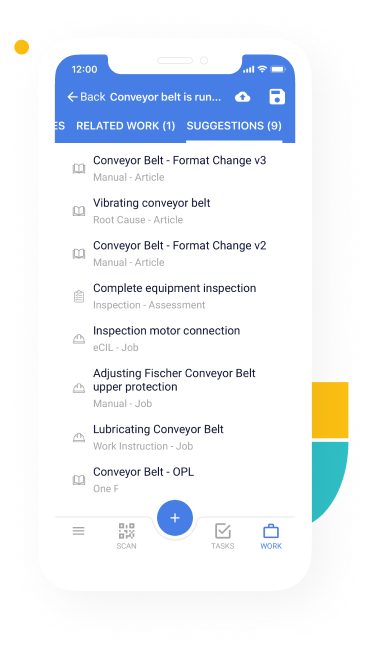

To this end, connected worker platforms include mobile-enabled knowledge management systems that workers can easily access on the shop floor.

If, for example, a breakdown is detected, the application automatically suggests countermeasures and checklists, saving operators time and empowering them to resolve the issue quickly.

These knowledge management systems also aggregate knowledge articles like standard operating procedures (SOPs), which can even help keep planned downtime to a minimum.

For one, these systems always provide the latest version of the article. And because the knowledge base is accessible via smartphones or tablets, workers no longer waste time searching for and fetching the knowledge item.

Create a performance baseline

Small stops and slow cycles can be difficult to track — especially if you’re using paper-based processes.

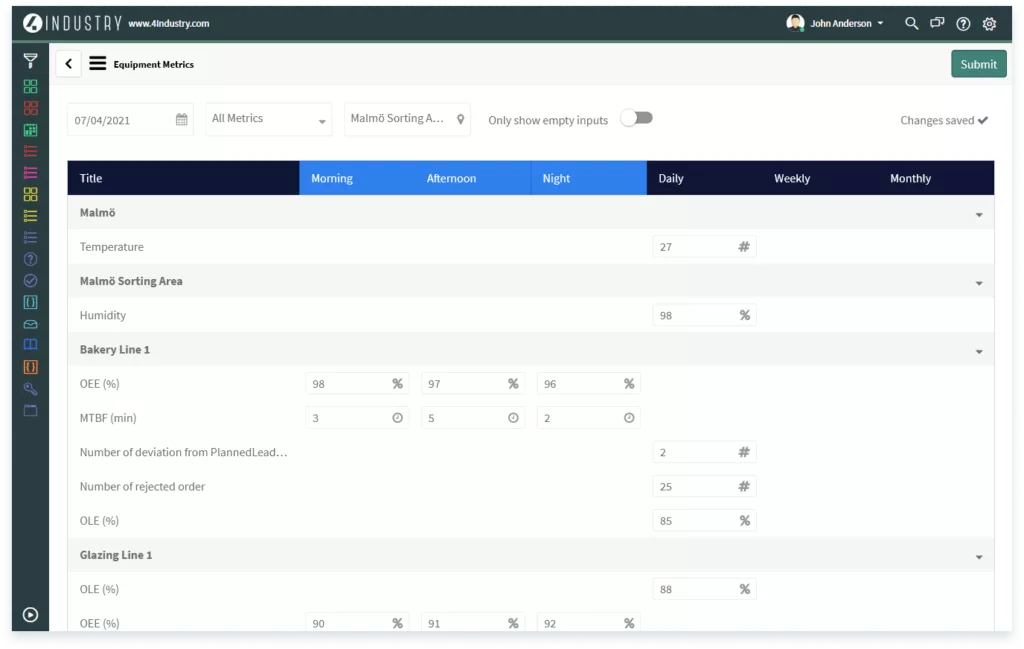

Connected worker platforms like 4Industry enable you to register your equipment, tools, and other assets, providing a helpful visualization of how all your machines are interconnected. With this feature, you can better understand what the problem is and where it is located.

These platforms also gather data from connected sensors and other Internet of Things (IoT) devices, creating a performance baseline from which the application can flag deviations.

The platform makes it easy to notify personnel and assign tasks whenever a deviation is detected, and you can even use the historical data to pinpoint maintenance focus areas.

Minimize defects with thorough, interactive work instructions

It can be easy to accidentally skip a small step when starting up a machine. However, these mishaps can lead to subpar product quality, costing you both time and materials.

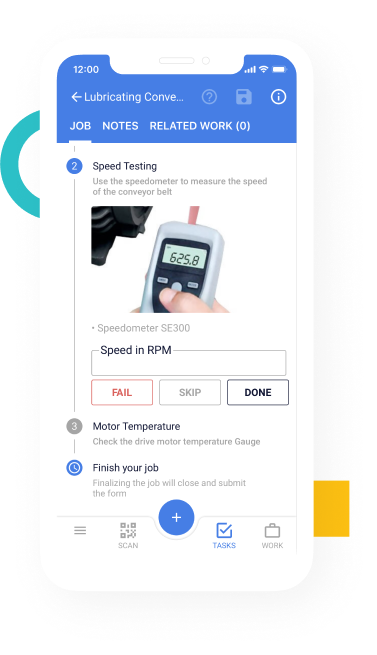

Connected worker platforms provide task management tools that let you easily schedule planned checkups and CIL tasks. When a job is due, the application automatically notifies relevant workers, helping them resolve the issue quickly.

The platform further supports workers by providing interactive digital forms and step-by-step checklists, accompanied by images and videos, to aid the operator in completing each procedure correctly.

In addition, these interactive instructions give newer operators the confidence they need to perform their jobs effectively.

Workers have instant access to all the necessary information, and more experienced operators can easily share their expertise by creating new knowledge articles or provide feedback on existing ones.

This allows you to minimize the Six Big Losses and improve your OEE.

Related Articles

Digitize your inspections, audits and checklists

4Industry targets Nordic market via strategic partnership with Advania