How a Connected Worker Platform Enhances Production Start-up Checklists

Discover how digital technology enhances production start-up checklists and benefits continuous improvement, training, and efficiency.

Production start-up checklists are used in manufacturing to guide operators in getting a production line running in a smooth and efficient way. Often being used multiple times a day, these versatile tools have a wide range of benefits for training, error reduction, quality, and continuous improvement.

In this blog, we’ll run you through the ins and outs of production start-up checklists. Additionally, we’ll give you tips on how you can boost their effectiveness by digitalizing them with a Connected Worker Platform.

Let’s get started.

What is a production start-up checklist?

A production start-up checklist is a manufacturing tool that guides operators through the correct adjustment of equipment settings, thereby getting a production line running quickly and mistake-free. A production start-up checklist is often attuned to a specific machine or product, the optimal settings of which can be determined through centerlining.

Production lines consist of several machines, each with its unique settings. Dialling, adjusting, and checking these can take a long time, delaying production and leading to tremendous waste.

It’s therefore key that operators have the right information to get everything running with the correct specifications immediately—and for this reason, production start-up checklists were brought into being.

How are production start-up checklists used?

A small number of factories uses start-up checklists in paper form as guidance and to record machine information that can be used for continuous improvement (CI) purposes.

Less advanced factories may use an SOP or work instruction to guide workers in getting production running.

They may also rely on an expert operator’s experiential knowledge. This way of working is naturally error-prone and even risky: the absence or retirement of an operator with vital knowledge can lead to an extended period of sub-optimal production.

It should be clear that production start-up checklists are a must to eliminate any waste at the beginning of production.

They’re also a useful training tool that helps inexperienced operators prepare complex machines for production.

And furthermore, any data recorded on start-up checklists about pre-production machine settings can be leveraged to drive CI.

The right digital shop floor solution can leverage and even enhance these benefits, turning start-up checklists into powerful efficiency-boosting tools.

Let’s explore the advantages of digitalized production start-up checklists.

The benefits of digitalizing your production start-up checklists

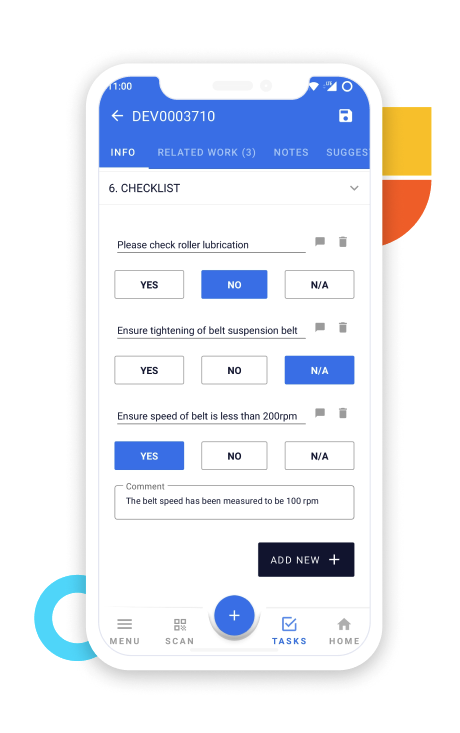

A Connected Worker Platform like 4Industry can digitalize production start-up checklists so that they can be accessed on a ruggedized smartphone or tablet.

An obvious advantage of this is that it eliminates the need to print, handle, and store paper—but the benefits don’t end there.

As start-up checklists are sometimes used multiple times a shift, embedding them in a streamlined, media-rich digital environment can significantly reduce waste and prevent adjustment errors.

All of your factory’s start-up checklists can be stored in one place, enriched with videos and images, and made easily retrievable so that all information to get production started is only a few taps of the finger away.

Furthermore, if the start-up machine settings ever need to be updated, that can be done instantaneously and factory-wide.

How digital start-up checklists improve training

Your seasoned operators carry a lot of valuable knowledge in their heads; after decades of experience, getting a line running is as straightforward to them as anything.

But transferring that knowledge to inexperienced operators and getting them up to speed quickly is no easy challenge.

A Connected Worker Platform’s Knowledge Management capabilities tackle this problem by making it easy for experienced operators to capture their historic knowledge.

This can then be turned into a standardized start-up checklist that, combined with explanatory visual media, can be used as a training tool for greenhorns.

As these digital instructions are much easier to understand than paper-based ones, inexperienced operators can in some cases even do unfamiliar things autonomously.

Continuous improvement benefits

The last major benefit applies to continuous improvement.

As already mentioned, a few advanced factories already use paper-based start-up checklists to record data for CI.

It’s obvious that paper is not the ideal format for data capturing, as it can easily get lost, be unreadable, and so on.

A centralized, cloud-based database can make this process entirely digital. Paper is safely eliminated and any necessary data for CI is immediately retrievable.

Results from CI projects can even be shared with other factories, turning your local start-up checklists into a tool with global impact.

The benefits of digital production start-up checklists in a nutshell

Digital production start-up checklists improve your shop floor operations in the following ways:

- Reduced waste

- Prevention or elimination of errors

- Improved efficiency

- Enables autonomous job execution for new operators

- Paperless data storage boosts continuous improvement efforts

- Prevent quality issues from occurring

Related Articles

Standardized Work: What It Is and How to Perfect It

How a Connected Worker Platform Accelerates Operational Excellence